The world of instant noodles thrives on convenience, but behind that simplicity lies a carefully engineered marvel of food science. At the heart of this innovation sits pregelatinized starch—an unsung hero that transforms dehydrated noodles into a steaming bowl of comfort within minutes. Unlike traditional starch, pregelatinized starch undergoes a thermal and mechanical treatment that breaks down its granular structure, allowing it to absorb water rapidly. This property is pivotal for instant noodles, where rehydration speed and texture determine consumer satisfaction.

When hot water meets instant noodles, a silent ballet of molecular reconfiguration begins. The pregelatinized starch granules, already partially swollen from their manufacturing process, act like microscopic sponges. They absorb water and swell further, creating a gel-like network that softens the noodle matrix. This process differs fundamentally from raw starch, which would require sustained heat to gelatinize—a luxury instant noodles can’t afford. The pre-treatment ensures that the starch reaches its maximum viscosity almost immediately, giving the noodles their characteristic springy bite without becoming mushy.

The manufacturing process of pregelatinized starch involves a delicate balance of heat, pressure, and shear forces. Starches—typically derived from wheat, potato, or tapioca—are cooked just past their gelatinization point before being rapidly dried. This creates a product that behaves like cooked starch but exists in a stable, shelf-ready powder. When instant noodle producers incorporate this ingredient into their dough, they’re essentially embedding countless tiny water portals throughout the noodle’s structure. These portals remain dormant until boiling water activates them, enabling uniform rehydration from surface to core.

Texture engineers in the instant noodle industry obsess over the degree of pregelatinization. Too little, and the noodles resist rehydration, leaving unpleasant hard spots. Too much, and the noodles disintegrate into a gluey mass. Advanced microscopy reveals how optimal pregelatinization creates a honeycomb-like microstructure in the dried noodles—a labyrinth of air pockets and thin starch walls designed to collapse in a controlled manner upon hydration. This explains why quality instant noodles maintain distinct strands rather than merging into a monolithic blob.

Climate adds another layer of complexity to this starch science. In humid environments, manufacturers often reduce pregelatinized starch content slightly to prevent premature moisture absorption during storage. Conversely, in arid markets, higher levels ensure reliable rehydration even with shorter steeping times. Some premium instant noodle varieties employ dual-starch systems—combining pregelatinized with native starches—to create textural contrasts that mimic fresh noodles. The interplay between these components can produce everything from the chewy udon-style strands to delicate ramen-like threads.

Recent breakthroughs in modified pregelatinized starches are pushing the boundaries further. Cross-linked variants now withstand longer cooking times without breaking down, enabling restaurant-style instant noodles that hold up in hot pots or prolonged simmering. Other innovations include starch-protein complexes that enhance nutritional profiles while maintaining superior rehydration properties. As consumer demand grows for cleaner labels, physical modification methods (using heat and pressure alone) are gaining preference over chemical treatments—a shift that’s reshaping entire supply chains.

The sustainability angle of pregelatinized starch deserves attention. By reducing the energy required for in-home noodle preparation (compared to traditional pasta cooking), instant noodles leverage this ingredient’s efficiency on a global scale. Researchers are exploring upcycled starch sources—like imperfect root vegetables or processing byproducts—to create next-generation pregelatinized starches without competing with staple food supplies. This circular approach could redefine what it means to eat conveniently while responsibly.

Looking ahead, the marriage of pregelatinized starch technology with 3D food printing promises customized noodle architectures. Imagine instant noodles with gradient densities—firm at the core but tender at the edges—or regional texture variations programmed into single packages. As the foundational element making all this possible, pregelatinized starch continues its quiet revolution, proving that sometimes the most profound innovations come in deceptively simple packets.

The art of baking a perfect cake relies heavily on understanding the science behind its structure. Among the many factors that contribute to a cake's texture, the uniformity of air pockets within the cake crumb stands out as a critical element. This characteristic is largely influenced by the foaming properties of proteins in the batter, particularly those found in eggs. The way proteins trap and stabilize air bubbles during mixing directly impacts the final product's lightness, tenderness, and overall mouthfeel.

The world of sensory evaluation is as intricate as it is fascinating, particularly when it comes to understanding how we perceive flavors and aromas. Among the myriad of compounds that contribute to our sensory experiences, vanillin—the primary component of vanilla extract—stands out for its widespread use and complex interaction with our senses. The concept of odor threshold plays a pivotal role in determining how much of this compound is needed for it to be detectable, and it varies significantly depending on the medium in which it is presented.

The world of chili peppers is as diverse as it is fiery, with each variety packing its own unique punch. At the heart of understanding this heat lies the Scoville Scale, a measurement that quantifies the spiciness of peppers. Developed by Wilbur Scoville in 1912, this scale remains the gold standard for gauging the capsaicin content—the compound responsible for that burning sensation—in different peppers. From the mild bell pepper to the mind-numbing Carolina Reaper, the Scoville Scale offers a fascinating glimpse into the spectrum of heat that chili enthusiasts chase.

The culinary world has long celebrated the magic that happens when certain ingredients come together, creating flavors greater than the sum of their parts. One such pairing—chicken broth and mushrooms—exemplifies the scientific and gastronomic phenomenon known as umami synergy. This dynamic duo has been a staple in kitchens across cultures, from French consommé to Japanese ramen, and its power lies in the way their compounds interact to amplify savory depth.

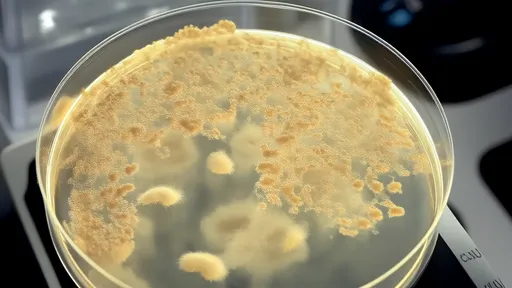

The world of fermented foods is a fascinating intersection of microbiology, chemistry, and culinary tradition. Among these, kimchi stands out not only for its bold flavors but also for the intricate biochemical processes that transform raw vegetables into a probiotic-rich delicacy. At the heart of this transformation lies a phenomenon known as acetic acid penetration, which creates a dynamic pH gradient during fermentation. This process is far more than a simple souring of cabbage—it's a carefully orchestrated dance between microbial communities and their chemical environment.

The turbidity of fruit juice, often perceived as a mark of freshness and natural quality, is primarily governed by the suspension mechanisms of pulp particles. These tiny fragments of fruit flesh, ranging from cellular debris to larger fibrous clusters, create the characteristic cloudiness that consumers associate with premium products. Behind this seemingly simple phenomenon lies a complex interplay of physical forces, biochemical interactions, and processing variables that determine whether pulp remains evenly dispersed or separates over time.

The fizz in your soda isn't just about taste—it's a carefully engineered dance between gas and liquid that begins unraveling the moment you twist open the cap. Few consumers realize how precisely carbonation levels are calibrated, or how dramatically pressure dynamics shift during that first explosive release. This invisible physics experiment in every bottle follows predictable but fascinating patterns that beverage scientists have spent decades mapping.

The world of espresso is as complex as it is captivating, with its rich flavors and aromatic allure. At the heart of this complexity lies a seemingly simple yet scientifically intricate component: the crema. This golden-brown layer of foam that crowns a well-pulled shot of espresso is not just a visual delight but a fascinating study in colloidal stability. The interplay of oils, gases, and solids in espresso crema reveals a delicate balance that defines the quality and texture of the coffee.

The phenomenon of "cold turbidity" or "cream down" in tea has long intrigued both tea connoisseurs and scientists alike. This natural occurrence, where tea liquor turns cloudy upon cooling, is not merely an aesthetic curiosity but a window into the complex chemistry of tea. Recent advancements in optical measurement techniques have enabled researchers to quantify this phenomenon through turbidity detection based on tea liquor transmittance, opening new avenues for quality assessment and understanding of tea's molecular interactions.

The world of instant noodles thrives on convenience, but behind that simplicity lies a carefully engineered marvel of food science. At the heart of this innovation sits pregelatinized starch—an unsung hero that transforms dehydrated noodles into a steaming bowl of comfort within minutes. Unlike traditional starch, pregelatinized starch undergoes a thermal and mechanical treatment that breaks down its granular structure, allowing it to absorb water rapidly. This property is pivotal for instant noodles, where rehydration speed and texture determine consumer satisfaction.

The world of traditional fermented foods holds countless microbial secrets, and few are as fascinating as the complex ecosystem of laomian – the centuries-old sourdough starter that gives Chinese steamed bread its distinctive character. While modern bakeries increasingly rely on commercial yeast, artisanal producers across northern China still maintain their family laomian cultures like precious heirlooms, passing down not just techniques but living microbial communities through generations.

The sticky, chewy texture of glutinous rice cakes, known as mochi in Japanese or nuòmǐ cí in Chinese, has long been a staple in East Asian cuisine. These delectable treats, often enjoyed during festivals or as everyday snacks, owe their unique consistency to a key component: amylopectin, the branched-chain starch found in glutinous rice. However, anyone who has left mochi or Chinese mochi cakes (糍粑) at room temperature for a few hours will notice an unmistakable transformation—the once-soft and pliable dessert gradually hardens, becoming tougher and less enjoyable. This phenomenon, often referred to as retrogradation, is a fascinating interplay of chemistry, physics, and culinary science.

The art of cooking perfect rice lies in understanding the gelatinization temperature of different japonica rice varieties. This scientific parameter, often overlooked by home cooks, determines the precise moment when starch granules absorb water and swell—fundamentally shaping texture, flavor release, and nutritional accessibility. Recent studies across Asian research institutions reveal how subtle genetic variations in short-grain rice cultivars create distinct thermal behaviors during cooking, challenging the one-size-fits-all approach to water ratios and heat application.

The art of crafting perfect hand-pulled noodles lies in mastering the delicate balance between gluten development and dough relaxation. Among the many variables that influence noodle extensibility, resting time stands as one of the most critical yet often overlooked factors. This silent alchemy occurring during the waiting period transforms a stiff, unyielding mass into an elastic, cooperative material ready to be stretched into silky strands.

For generations, home cooks and professional chefs alike have relied on stainless steel containers for pickling and food storage. The material's reputation for durability and corrosion resistance makes it a seemingly ideal choice. But when acidic ingredients like vinegar enter the equation, questions arise about potential metal leaching and food safety. Understanding the interaction between stainless steel and pickling brines requires a deeper dive into metallurgy, chemistry, and culinary science.

The bamboo steamer, a centuries-old culinary tool cherished across Asian kitchens, operates on principles far more sophisticated than its simple appearance suggests. Among its most fascinating phenomena is the so-called "bamboo steamer effect" – a self-regulating mechanism that prevents the dreaded condensation drip-back, ensuring perfectly textured dumplings, buns, and fish every time. This natural engineering marvel has captivated chefs and scientists alike, revealing how traditional wisdom often anticipates modern food science.

The age-old practice of stone milling has long been revered for its ability to produce flour that retains the natural goodness of whole grains. Unlike modern industrial milling methods, which often prioritize speed and shelf life, stone grinding operates at a slower pace, preserving the integrity of the grain’s nutritional profile. One of the most significant advantages of this traditional method is its ability to maintain higher levels of dietary fiber in whole wheat flour—a component essential for digestive health, blood sugar regulation, and overall well-being.